1.Requirements on the installation surface and installation site

If foreign objects such as iron filings, burrs, and dust enter the SKF bearing, it will cause noise and vibration during the operation of the SKF bearing, and may even damage the raceways and rolling elements. Therefore, before installing SKF bearings, you must ensure that the mounting surface and the installation environment are clean.

2.SKF bearings must be cleaned before installation

The surface of SKF bearings is coated with anti-rust oil. You must carefully clean them with clean gasoline or kerosene, and then apply clean high-quality or high-speed high-temperature lubricants before installation. The effect of cleanliness on SKF bearing life and vibration noise is very large. However, we would like to remind you that the fully enclosed SKF bearings do not require cleaning and refueling.

3.Selection of grease

Lubrication has a very important impact on the operation and life of SKF bearings. Here we briefly introduce the general principles of selecting grease. Grease is made of base oil, thickener and additives. The performance of different types and greases of the same type and brand is very different. The allowable rotation limit is different. Please pay attention when selecting. The performance of grease is mainly determined by the base oil. Generally, low viscosity base oil is suitable for low temperature and high speed, and high viscosity is suitable for high temperature and high load. The thickener is also related to the lubricating performance. The water resistance of the thickener determines the water resistance of the grease. In principle, different brands of greases cannot be mixed, and even greases of the same thickener will have adverse effects on each other due to different additives.

4.Adding grease

When lubricating, apply as much grease as possible. This is a common misconception. Excessive grease in SKF bearings and SKF bearings will cause excessive agitation of the grease, resulting in extremely high temperatures. The amount of SKF bearings filled with lubricant should be 1/2 to 1/3 of the internal space of SKF bearings. It should be reduced to 1/3 at high speeds.

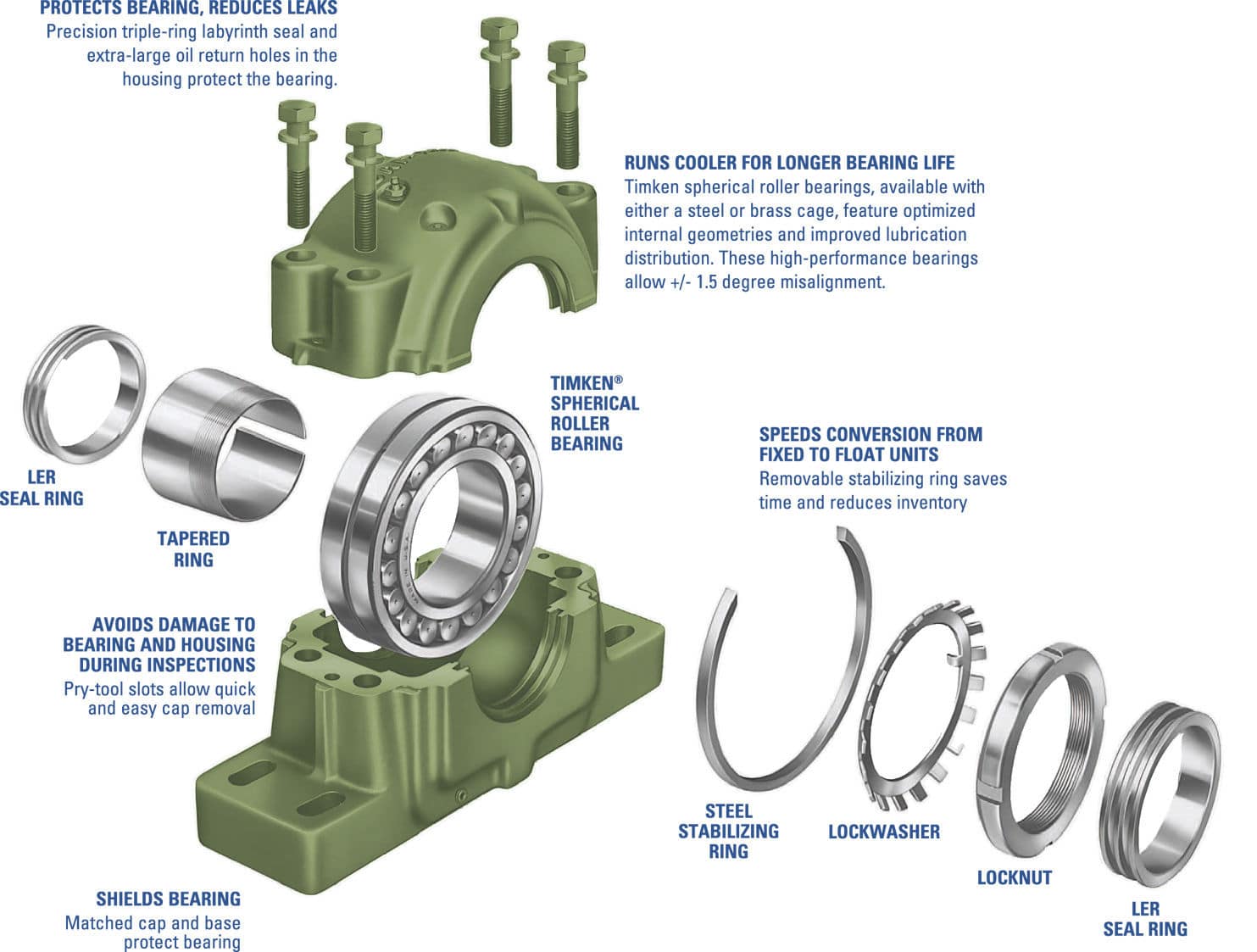

5.The installation and removal of SKF bearings

During installation, do not directly hit the SKF bearing end face and the non-stressed surface. Use compressing blocks, sleeves or other installation tools to uniformly force the SKF bearing. Do not install it through the rolling body transmission force. If the mounting surface is lubricated, installation will be smoother. If the interference is large, the SKF bearing should be placed in mineral oil and heated to 80 ~ 90 ℃, and then installed as soon as possible, and the oil temperature should be strictly controlled not to exceed 100 ℃ to prevent the tempering effect from reducing the hardness and affecting the size recovery. When you encounter difficulties in disassembly, it is recommended that you use a disassembly tool to carefully spray hot oil on the inner ring while pulling outwards. The heat will expand the inner ring of the SKF bearing, making it easier to fall off.

DESUN BEARING LIMITED

Add:ROOMS 1401-2,EASEY COMMERCIAL BUILDING,253-261 HENNESSY ROAD,WANCHAI,HONG KONG

Tel :

00852 30697280

Fax:

00852 30697280

E-Mail:Sales@desunbearing.com